MARKET

inspection.

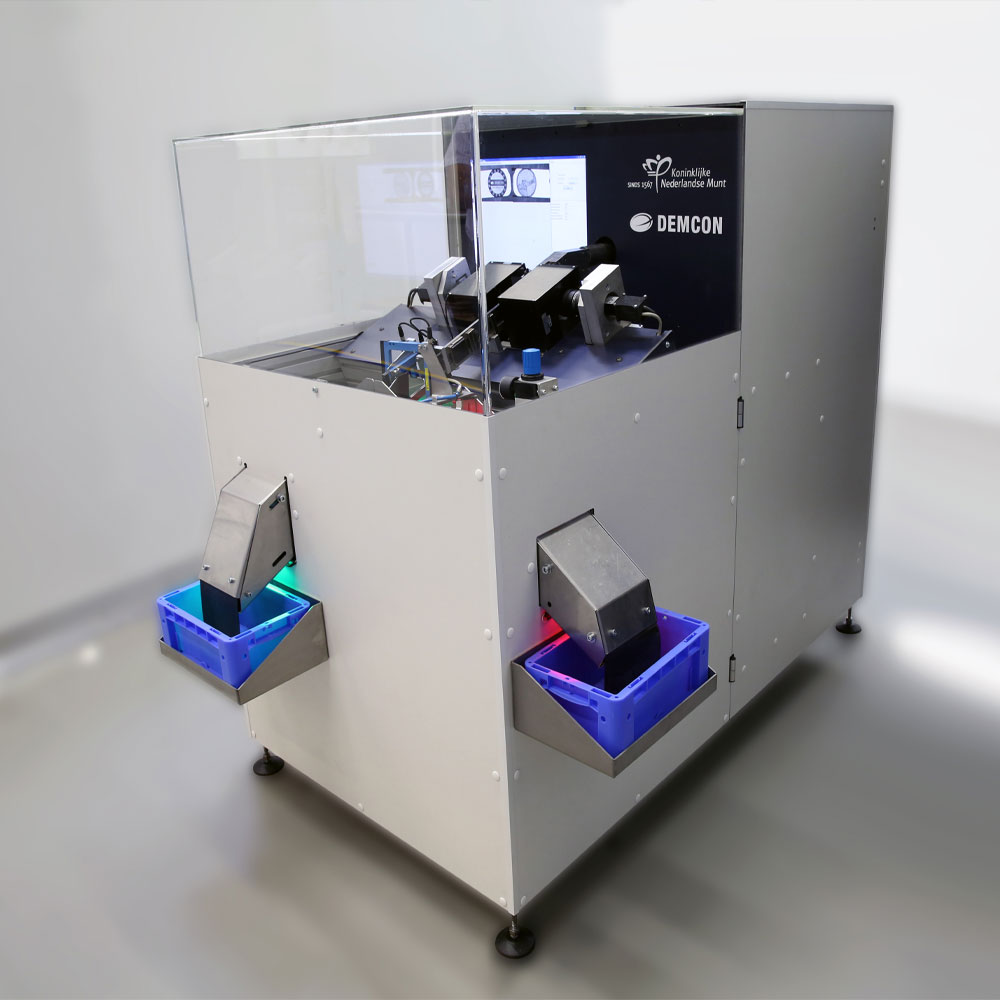

Inspection is crucial for controlling and further increasing the quality of production. We develop reliable inspection solutions for challenging product qualifications, ranging from innovative laboratory setups to efficient industrial systems. For this we use our comprehensive expertise in computer vision, high-precision metrology and optical metrology, artificial intelligence and robust industrialization.

QUALITY ASSURANCE AND PROCESS OPTIMIZATION

high-precision and high-volume inspection.

Industrial quality control for complex products requires advanced, frequently vision-based, inspection solutions. We are specialized in high-precision 2D- and 3D-shape measurements for qualification, recognition, alignment, calibration and defect detection purposes. Our inspection expertise covers a variety of product characteristics for a wide range of materials; from glass, metal, plastics and (non)-woven fabrics to composite, rubber and organic materials. We develop six-sigma inspection algorithms, often based on comparison with CAD data, and use deep learning and neural networks for image analysis. When real-life data are scarce, we train the algorithm with synthetic (simulated product) data.

“we help to increase quality as well as efficiency in production.”

We deliver turnkey automated inspection solutions integrated as closed-loop systems in a production line, for real-time, 100% quality control. This enables manufacturers to increase quality as well as efficiency in production. Our strength lies in the combined expertise of mechanics, optics, software and AI. For example, our proprietary software platform is compatible with most camera, PLC and computer systems, and various imaging, data and event logging formats – thus greatly reducing software development effort.